Steel Erecting

Quality and Precision for Steel Erecting

Steel Erecting is the backbone of new construction for skyscrapers, bridges, stadiums and more. It is the process of constructing and installing different types of structural steel to create the frame or skeleton of a structure. This is a very complex process that involves plan drawings being executed by a team consisting of supervisors, ironworkers, welders, crane operators and more. Each individual has an important role. By working together with blue prints, the team is able to safely and efficiently assemble steel structures. Steel Erecting in the United States typically requires specific types of structural steel shapes and grades according to the American Society for Testing and Materials (ASTM). We carry a wide range of steel products to ensure the material for your project is in compliance with ASTM.

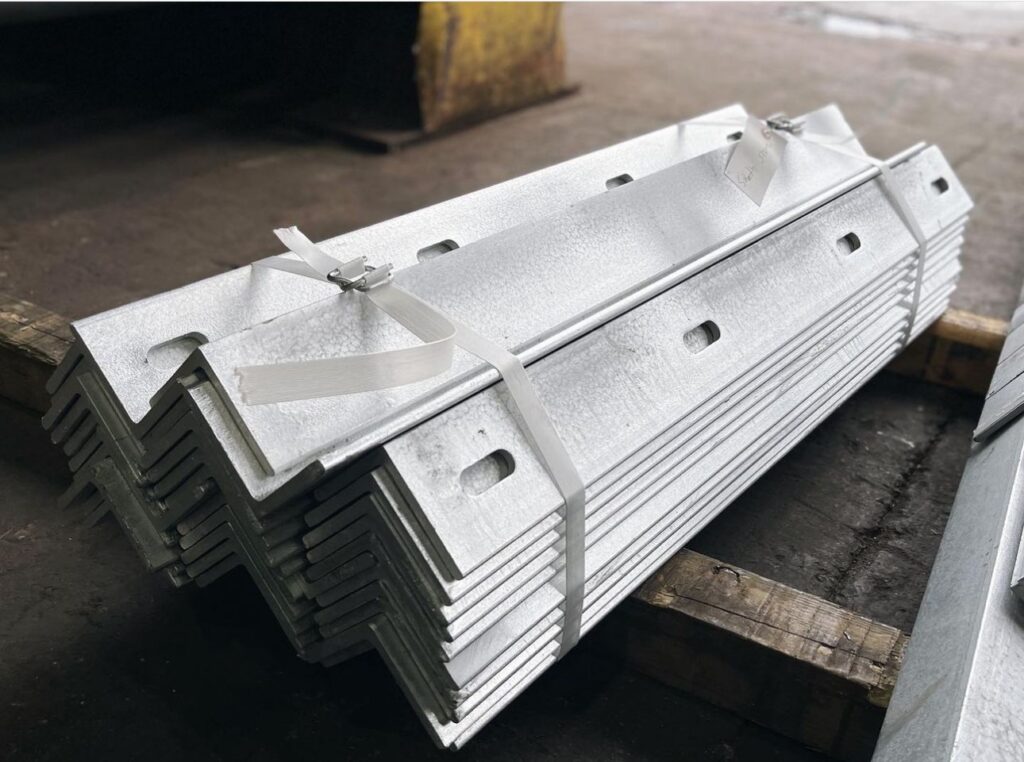

Steel erecting is one of the largest industries that we supply and fabricate steel products for in New York, New Jersey, and Pennsylvania. We work closely with steel erectors in the Tri-State area to fabricate steel plates, beams, angles, and other structural steel shapes. These jobs demand close collaboration with erectors and diligent attention to plan drawings to ensure precise fitting of all structural components and to guarantee a smooth installation process. One of our previous projects included providing stress bar plates that were used to build the foundation of the Freedom Tower in New York City. Additionally, we provided 3” and 4” A514 steel plates to the Wittpenn Bridge which connects Jersey City and Kearny. These are just a few examples of the thousands of structures that we have provided steel for in the Tri-State area.

Ready for your next project?

Contact us for Competitive Pricing.

Type of Steel Used In This Industry

Angles

Channels

H-Pile Beams

Rebar

Round Bar

Steel Plate – ASTM A-36, ASTM A-572, ASTM A-588, ASTM 516-GR70, and ASTM A-514

Tubing

Wide Flange Beams